Our Advanced Technology

Our fully integrated system works together to create a level of efficiency that allows doctors to visualize the end result and deliver in a whole new way.

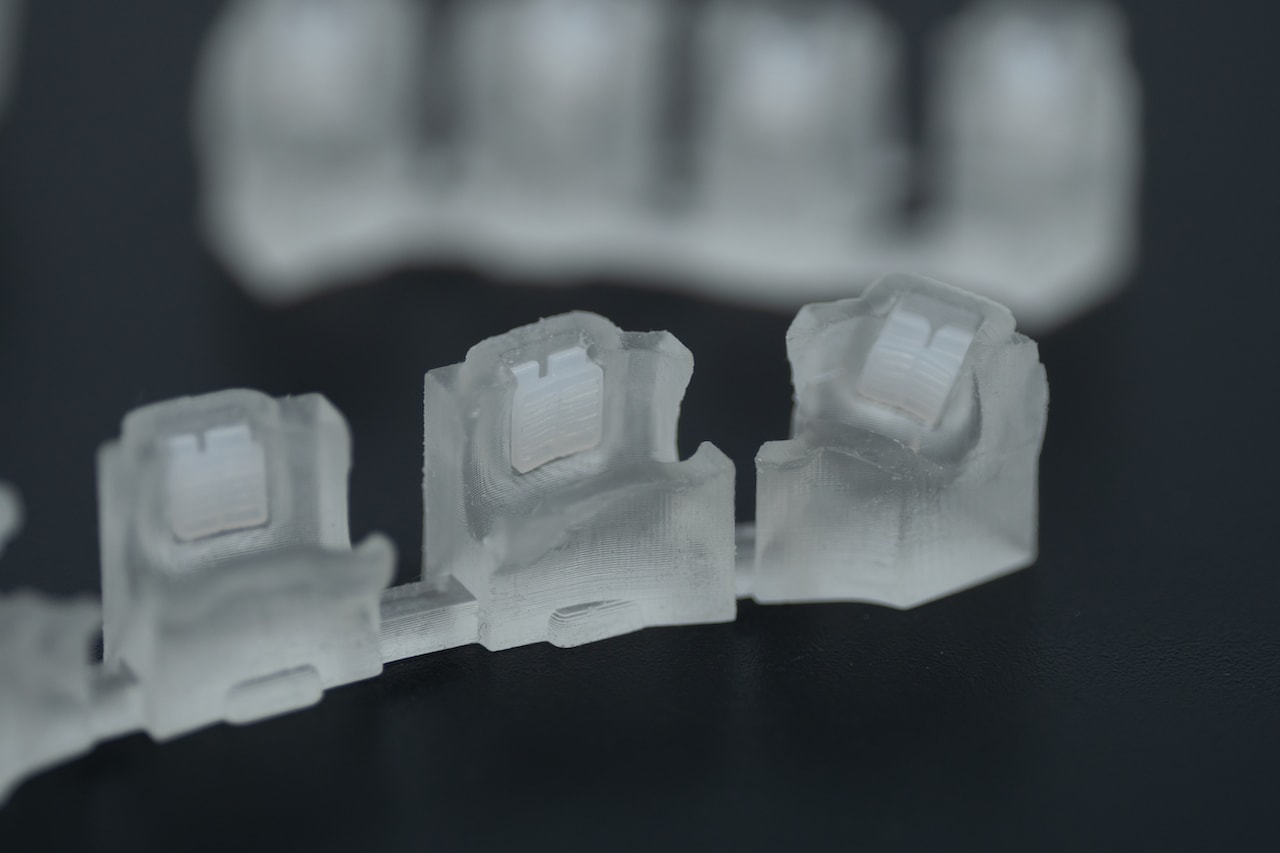

LIGHTFORCE HARDWARE

A full 7-7 fixed appliance system that includes our 3D printed fully custom brackets and IDB trays.

LEARN MORE ABOUT LIGHTFORCE HARDWARE

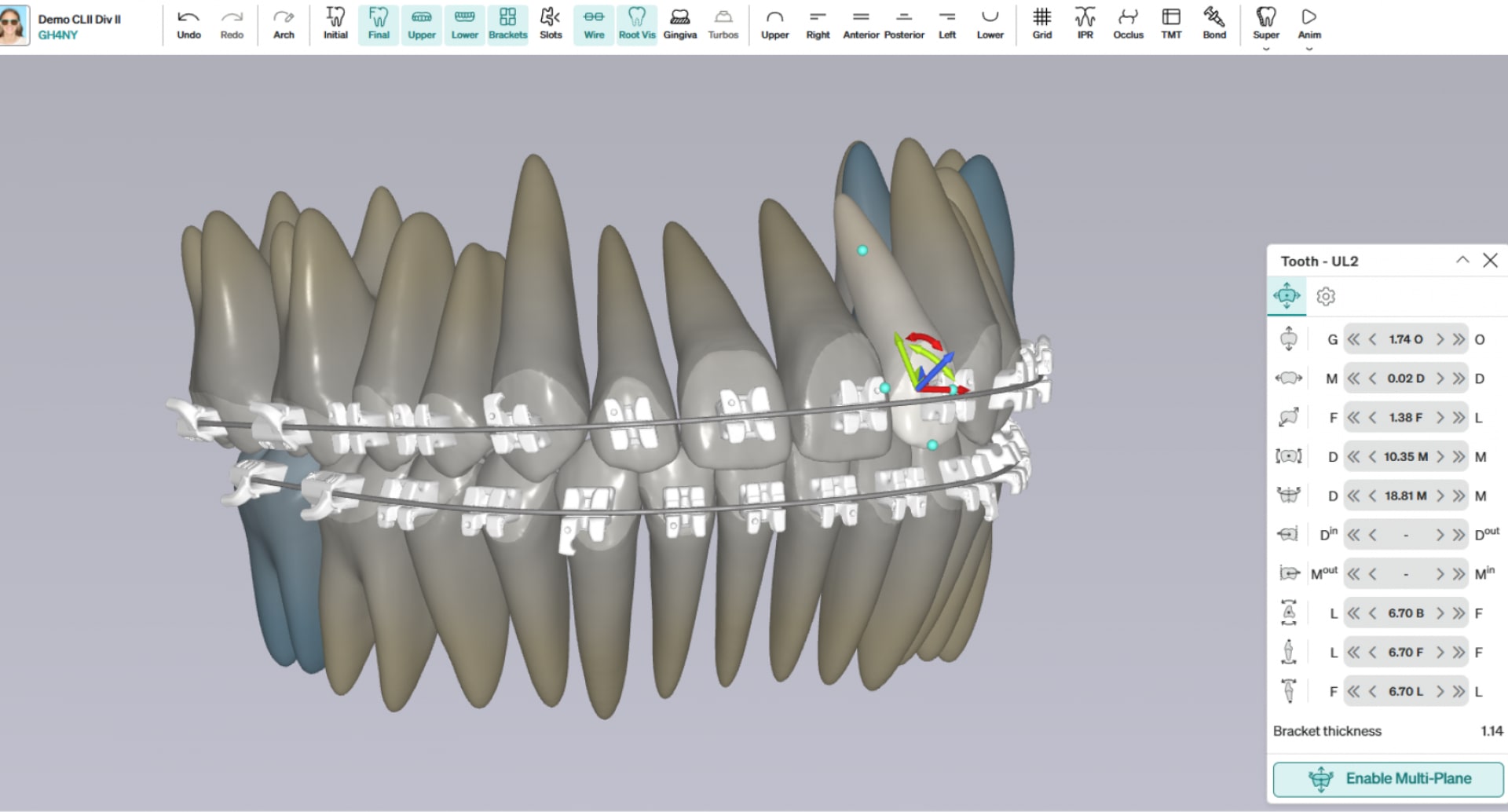

LIGHTFORCE SOFTWARE

LightForce software is an easy-to-use tool for digital treatment planning. The web-based platform enables you to create, adjust, and approve treatment plans quickly and easily.

Get Started with LightForce Today

BOOK A DEMOBlog

LightForce Orthodontics Secures $50 Million Series C Funding Led By Kleiner Perkins

Investment fuels further development of 3D printing technology to create custom orthodontic treatments for every patient.

Save Time and Increase Efficiency with LightForce’s Custom Rebond IDB Trays

Picture this: You've just gotten home from a long day at the practice when you get a call that a patient's bracket has broken off. What do you do? With LightForce, a break doesn't have to derail your day. Our custom-built, easy-to-use rebond IDB trays enable orthodontists to delegate rebonding to staff while ensuring that brackets are attached precisely every time.

Illuminate Podcast: Dr. Alfred Griffin and Dr. Chris Cetta Talk All Things LightForce

In a recent episode of the Illuminate Orthodontics podcast, LightForce’s CEO Alfred Griffin sat down with Dr. Chris Cetta. Over a couple of Manhattans, they discuss how Dr. Griffin became interested in orthodontics, the birth of LightForce, and some of the biggest challenges and growth moments the company has experienced over the past year.